Quality Guaranteed: A Buyer's Guide to Certifications and Technologies Among Bangalore Sheet Metal Fabricators

In Bangalore, the capital of Indian engineering, the standard for manufacturing excellence is non-negotiable. This thriving metropolis, home to global giants in aerospace, automotive, and IT infrastructure, demands a level of quality that traditional fabrication cannot meet. It is in this high-stakes environment that sheet metal fabrication companies in Bangalore prove their worth, with sheet metal fabrication serving as an essential, transformative process that meticulously converts flat raw material into robust, functional parts that enable everything from satellite systems to high-performance defense equipment.

For businesses looking to launch a new product, scale up production, or source reliable components, finding the right fabrication partner in this sprawling metropolis is a critical decision. This comprehensive guide delves deep into the Bangalore sheet metal fabrication landscape, profiling the top players, outlining the latest technological trends, and providing an actionable checklist for selecting your ideal fabrication partner—a partner like Zeometrix.

The Industrial Ecosystem: Why Bangalore Leads the Fabrication Field

Bangalore’s unique strength as a fabrication hub stems from its concentrated presence of high-technology end-users, which necessitates an equally high standard from its vendors. The city’s fabrication industry is characterized by its adaptability, having seamlessly integrated the precision of software-driven design with the robustness of physical manufacturing.

Key Demand Drivers in Bangalore:

-

Aerospace & Defence: Home to HAL, ISRO, and a vast network of Tier-1 and Tier-2 suppliers, the city demands fabrication with aerospace-grade tolerances and material quality (e.g., in components for landing gear or engine enclosures).

-

Electronics & IT Infrastructure: The massive need for server enclosures, racks, chassis, and sophisticated electronic housings for data centers and IT parks drives a major segment of the precision sheet metal market.

-

Automotive & Electric Vehicles (EVs): With the rapid rise of EV manufacturing, the demand for battery storage structures, custom brackets, and lightweight body panels is seeing exponential growth.

-

Medical Equipment: The manufacturing of high-precision components for diagnostic and surgical machinery requires stringent quality control and high-grade stainless steel fabrication.

This demanding environment has forced Bangalore’s fabrication companies to invest heavily in advanced technology, transforming the industry from basic metal-bending workshops into sophisticated, integrated manufacturing facilities.

The Vanguard of Precision: Top Sheet Metal Fabrication Companies in Bangalore

When seeking a fabrication partner, it’s essential to look beyond the basic capability and focus on specialized experience, technology, and industry certifications. While many companies contribute to the city’s industrial might, a few stand out in terms of technological adoption and client base.

1. Zeometrix: Precision Engineering for the New Age

-

Specialization: Advanced, end-to-end precision sheet metal solutions focusing on rapid prototyping and medium-to-high volume production.

-

Key Capability: Zeometrix integrates state-of-the-art Fiber Laser Cutting and multi-axis CNC Bending with complete in-house finishing and assembly. We emphasize strict compliance with international quality standards, delivering solutions for mission-critical applications in sectors like telecommunications, medical devices, and defense. Our focus is on seamless transition from CAD design to final product delivery, backed by transparent project management.

-

Industry Focus: Telecom, Medical, Defense, and Industrial Electronics.

2. Rishi Laser Limited

-

Specialization: High-Volume Sheet Metal Fabrication and Contract Manufacturing.

-

Key Capability: Recognized for large-scale production, utilizing advanced features like 5-Axis 3D Laser Cutting and Robotic Welding Cells to maintain consistency and rapid scaling, particularly for automotive and heavy industrial clients.

-

Industry Focus: High-Volume, Industrial, and Automotive sectors.

3. PRK Fabricators Pvt. Ltd.

-

Specialization: Comprehensive Component Manufacturing.

-

Key Capability: Known for servicing diverse sectors, including food processing, aerospace, and general machinery, with strong foundational capabilities in punching, bending, and specialized TIG/MIG welding.

-

Industry Focus: Automotive, Aerospace, Medical, and Food Processing.

4. Fine Punch Fab Ltd

-

Specialization: Precision Sheet Metal and Structural Fabrication.

-

Key Capability: Boasts ultra-modern manufacturing equipment, including CNC Turret Punch Presses and Robo Welding capabilities. Their strength lies in handling a wide variety of materials, including MS, GI, Aluminium, and Copper, with an emphasis on cost-effective, precise components.

-

Industry Focus: Electronics, Commercial, and general Industrial sectors.

Navigating the Future: Trends in Bangalore’s Sheet Metal Industry

The fabrication market is not static; sheet metal production is evolving rapidly, driven by technological adoption and global industry shifts. A forward-thinking client must understand these trends:

|

Trend |

Description & Impact on the Buyer |

|

Industry 4.0 & Automation |

Increased adoption of Robotic Welding and advanced CNC machines (like fiber laser cutters and high-tonnage press brakes) reduces manual error, ensuring higher precision, faster turnaround times, and consistent quality, even at high volumes. |

|

Sustainability & Green Materials |

Growing focus on using highly recyclable materials (steel, aluminum) and waste reduction strategies. Buyers will see requests for material sourcing transparency and adherence to environmental norms. |

|

Design Integration (BIM & CAD) |

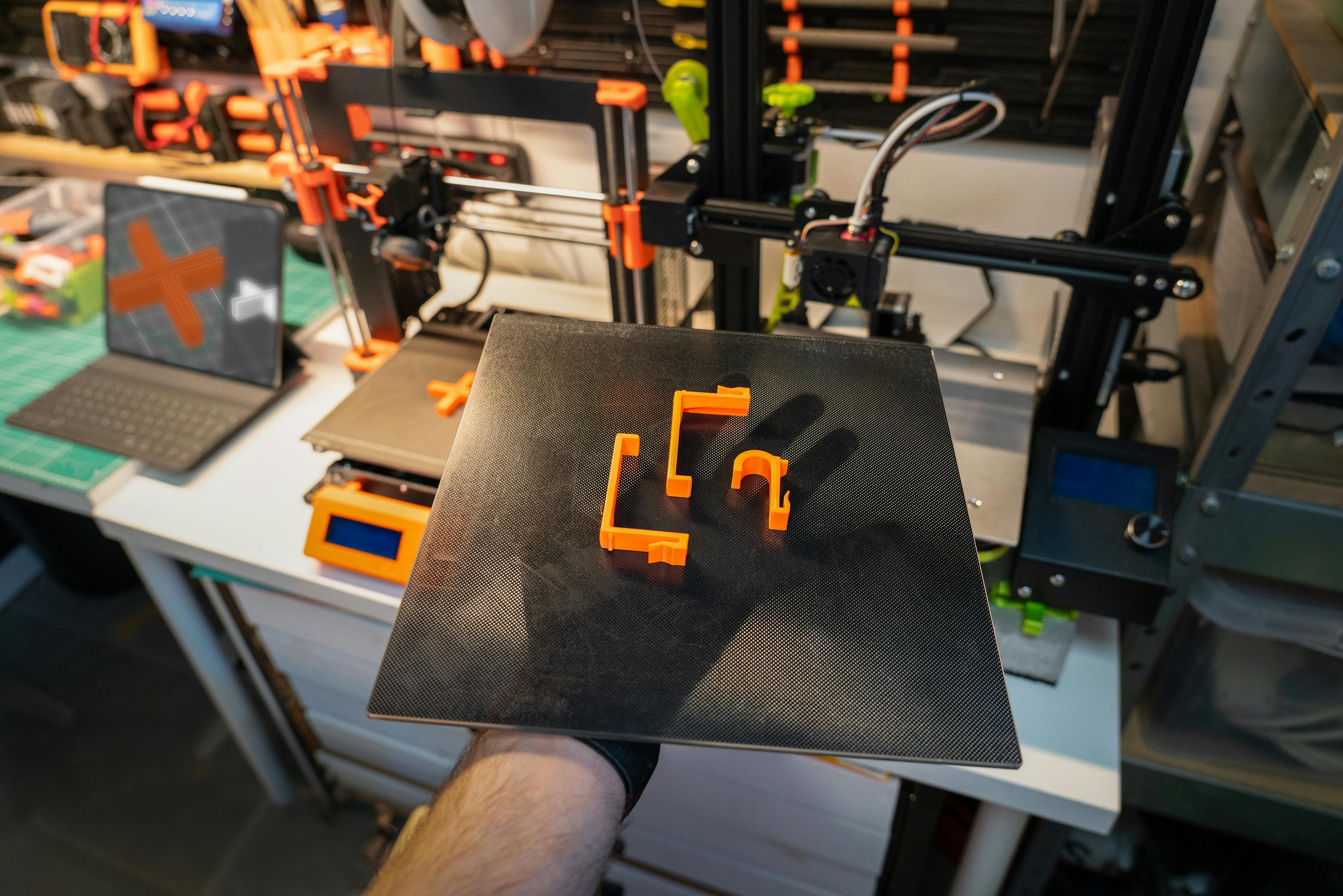

Fabricators are integrating Building Information Modeling (BIM) and sophisticated 3D CAD software. This allows for seamless design-to-production workflows, enabling rapid prototyping and error reduction before the first cut is made. |

|

End-to-End Solutions |

Companies like Zeometrix are moving beyond 'job work' to offer full contract manufacturing—providing design consultation, fabrication, finishing (powder coating, anodizing), and final assembly/kitting, streamlining the supply chain for clients. |

A Deep Dive into Fabrication Technologies: The Process Matters

The heart of precision sheet metal lies in the tools used. The choice between core cutting technologies determines speed, accuracy, material compatibility, and ultimately, cost.

1. Cutting Technologies: Speed vs. Precision

|

Technology |

Process Description |

Best Application |

|

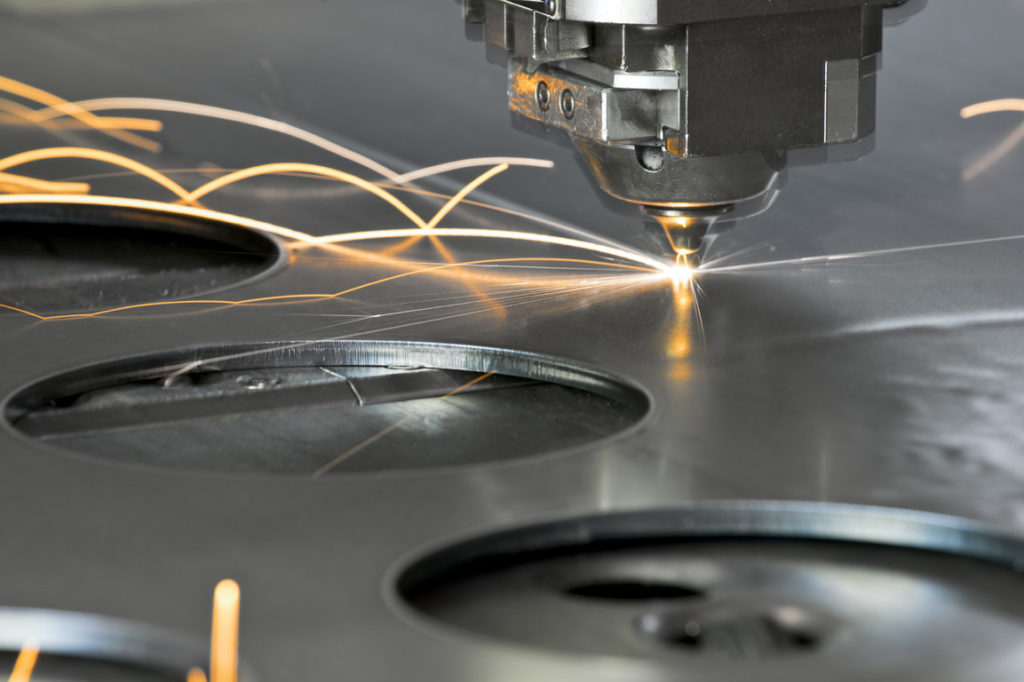

CNC Fiber Laser Cutting |

A high-energy laser beam is focused to melt/vaporize the metal. Controlled by CNC. |

High Precision and Intricate Geometry. Ideal for thin-to-medium gauge metals (MS, SS, Al, Copper) where complex contours and tight tolerances are required. Low Heat Affected Zone (HAZ). |

|

CNC Turret Punching |

A punch and die shear the material to create holes or contours. Extremely fast for repeated shapes/holes. |

High-Volume Production and Standard Shapes. Most cost-effective for parts with many standard features (like vents or mounting holes) in materials up to $3 \text{mm}$ thick. |

|

Waterjet Cutting |

Uses an abrasive-entrained, high-pressure water stream. |

Exotic Materials or Heat-Sensitive Alloys. Best when the material cannot tolerate any heat (no HAZ) or for cutting very thick plate or non-metals. |

2. Forming Technologies: The Art of the Bend

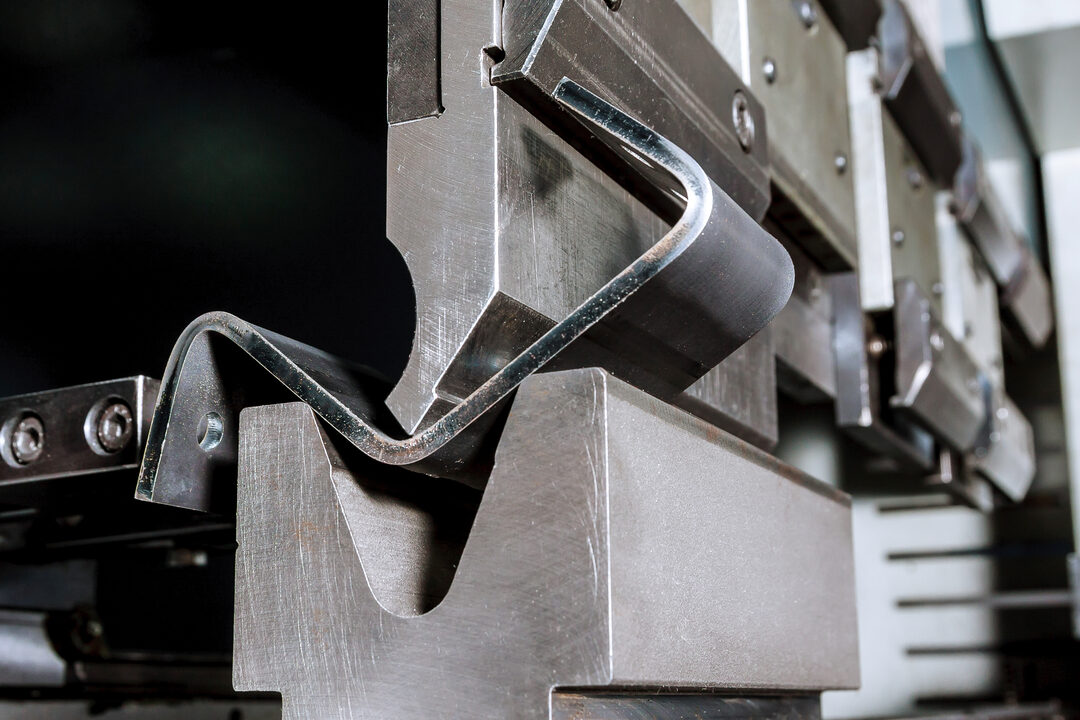

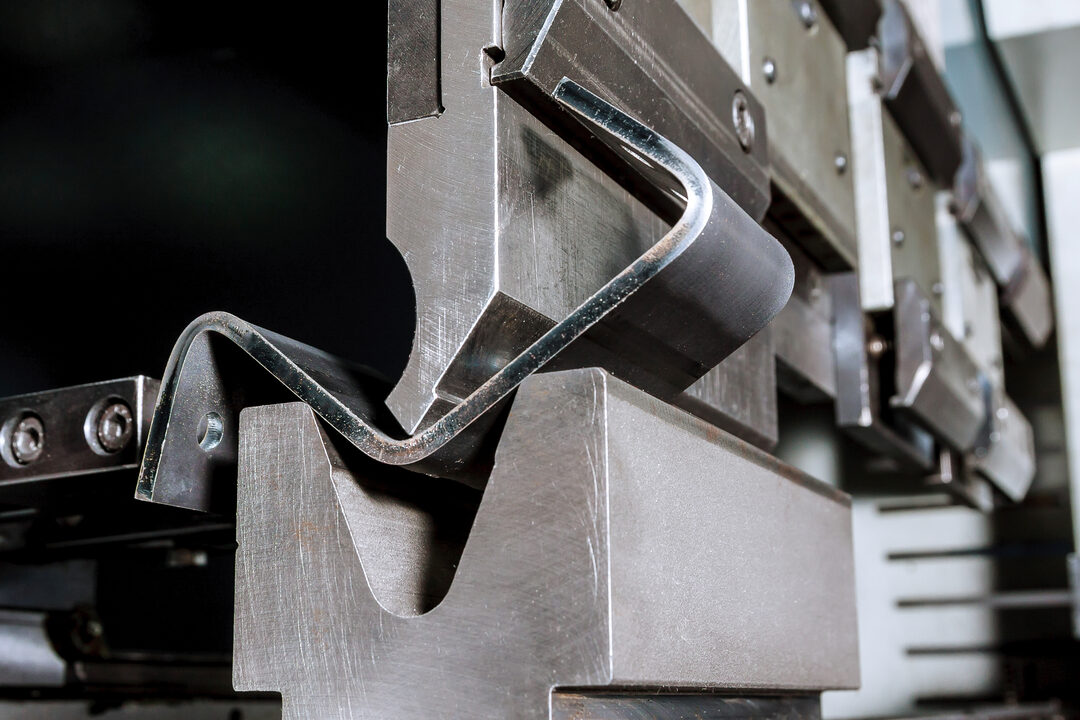

Once cut, the flat "blank" must be formed into its 3D shape, typically using a CNC Press Brake. This machine applies force to the sheet metal, forcing it into a die to create the desired angle. The quality of a fabricator is often judged by the precision of their press brakes, which should be capable of producing consistent $V$, $U$, or channel bends with minimal spring-back error.

3. Joining Technologies: Strength and Sealing

-

TIG/MIG Welding: The two most common methods. MIG (Metal Inert Gas) is faster and often used for thicker or less critical materials (MS, general fabrication). TIG (Tungsten Inert Gas) is slower but produces the highest quality, cleanest, and strongest welds, critical for stainless steel, aluminum, and aerospace components.

-

Spot Welding: Used to join two overlapping sheets without using filler material. It’s fast and cost-effective for internal structural support, such as chassis work.

-

Hardware Insertion (PEM/Riveting): Specialized automated pressers are used to insert self-clinching fasteners (PEM nuts, studs) accurately and quickly into prepared holes, eliminating the need for tapping or loose hardware.

The Ultimate Checklist: 8 Critical Factors for Choosing a Fabricator

Selecting the wrong partner can lead to costly delays, material waste, and product failure. Use this eight-point checklist to vet potential sheet metal fabrication companies in Bangalore:

1. Technology & Equipment Mastery

-

Ask: Do they use the latest-generation machinery? Look for high-wattage Fiber Laser Cutting and multi-axis CNC Press Brakes (to achieve complex bends).

-

Why it Matters: Advanced machinery directly correlates with higher precision, tighter tolerances ($+/-0.1\text{mm}$ to $+/-0.2\text{mm}$ being a common benchmark), and faster production cycles.

2. Experience in Your Specific Industry

-

Ask: Have they successfully completed projects for the aerospace, medical, or EV sector? Do they understand the specific material and compliance requirements of your end product? (A company like Zeometrix can provide case studies relevant to your sector).

-

Why it Matters: An experienced fabricator understands industry-specific standards and required certifications.

3. Quality Management & Certifications

-

Ask: Are they ISO 9001 Certified? Do they follow rigorous Quality Control (QC) processes like First Article Inspection (FAI) and utilize Coordinate Measuring Machines (CMM) for verification?

-

Why it Matters: Certifications demonstrate a commitment to standardized, repeatable processes. A robust QC system prevents defects from reaching the final assembly stage.

4. Material Sourcing and Transparency

-

Ask: Can they provide a clear Material Test Certificate (MTC) and trace the raw material (steel, aluminum, stainless steel) back to the mill?

-

Why it Matters: Transparent sourcing ensures you get the exact material grade you paid for, which is vital for product reliability, especially for high-stress or corrosion-critical applications.

5. In-House Capabilities vs. Subcontracting

-

Ask: Do they handle crucial finishing processes—like powder coating, polishing, galvanizing, or plating—in-house?

-

Why it Matters: In-house finishing capabilities (which Zeometrix maintains) reduce lead times, minimize logistics costs and damages, and allow the fabricator to maintain complete quality control from start to finish.

6. Design for Manufacturing (DFM) Expertise

-

Ask: Does the company offer DFM consultation before starting production? Can they suggest design modifications to reduce cost or improve durability?

-

Why it Matters: A true partner saves you money by optimizing your design for the fabrication process, avoiding unnecessary tooling and material costs.

7. Financial and Quoting Transparency

-

Ask: Is the quotation itemized? Does it clearly break down material cost, processing cost, and tooling/setup fees?

-

Why it Matters: Avoid the "lowest price trap." Focus on value. Transparent pricing helps you compare offerings and avoids hidden costs or material compromises.

8. Capacity and Scalability

-

Ask: Can they handle both your initial low-volume prototyping run and your subsequent high-volume production ramp-up without compromising lead times?

-

Why it Matters: Partnering with a scalable company prevents the expensive and risky process of switching suppliers as your business grows.

Conclusion: Forging Future Success with Zeometrix

Bangalore’s sheet metal fabrication industry is at the pinnacle of India’s manufacturing prowess, characterized by high-precision, cutting-edge technology, and a specialized workforce. For any business—from a fledgling hardware startup in Electronic City to a large-scale automotive OEM—the city offers a robust and competitive landscape.

The key to forging a successful partnership is due diligence: selecting a firm that not only has the right machines but also the right industry experience, quality certifications, and a commitment to communication. At Zeometrix, we are dedicated to being that partner—combining global-standard technology with local expertise to reliably turn your engineering designs into high-quality, market-ready products. By applying the checklist and understanding the core competencies of the top players, you can secure a fabrication partner that ensures your long-term success in India’s technological capital.

Frequently Asked Questions (FAQ) about Sheet Metal Fabrication in Bangalore

Q1: What are the typical lead times for a new sheet metal project in Bangalore?

A: Lead times vary based on complexity and volume.

-

Prototyping/Low Volume: Often $1$ to $3$ weeks for the first few units, as it involves CAD finalization, DFM review, and initial programming.

-

High Volume/Repeat Orders: Can be as fast as $1$ to $2$ weeks, depending on the material stock and finishing requirements. Reputable firms like Zeometrix offer express turnaround options for critical parts.

Q2: Which material is most commonly used by Bangalore fabricators, and why?

A: Mild Steel (MS) is the most common due to its low cost, excellent weldability, and strength, typically finished with powder coating to prevent corrosion. However, Stainless Steel (SS 304/316) is crucial for medical, food, and coastal applications due to its superior corrosion resistance, while Aluminum (Al 5052/6061) is preferred for aerospace and electronics enclosures where weight reduction and heat dissipation are critical.

Q3: What quality certifications should I look for beyond ISO 9001?

A: While ISO 9001 is standard, look for:

-

AS9100: Required for aerospace and defense components.

-

IATF 16949: Required for automotive suppliers.

-

RoHS Compliance: Increasingly necessary for electronic enclosures to restrict hazardous substances.

Q4: How does CNC Laser Cutting compare to CNC Punching in terms of cost?

A:

-

CNC Laser Cutting is typically more cost-effective for low-volume production and parts with complex geometries, as it requires no physical tooling costs.

-

CNC Punching becomes far more cost-effective for high-volume production runs where the initial tooling cost is amortized over thousands of parts. The speed of punching makes it unbeatable for creating many standard holes or shapes.

Q5: Is it better to choose a company with in-house finishing (e.g., powder coating) or one that outsources?

A: In-house finishing is strongly recommended. When finishing is outsourced, the fabricator loses control over the crucial last step of the process, which can lead to quality issues, longer lead times, and disputes over defects (e.g., poor adhesion, paint bubbles). Companies offering end-to-end services (like Zeometrix) ensure faster delivery and singular accountability for the final product quality.